- Connect With Us!

- +92 345 3230843

- +971 54 454 5232

- solutions(at)eispak.com

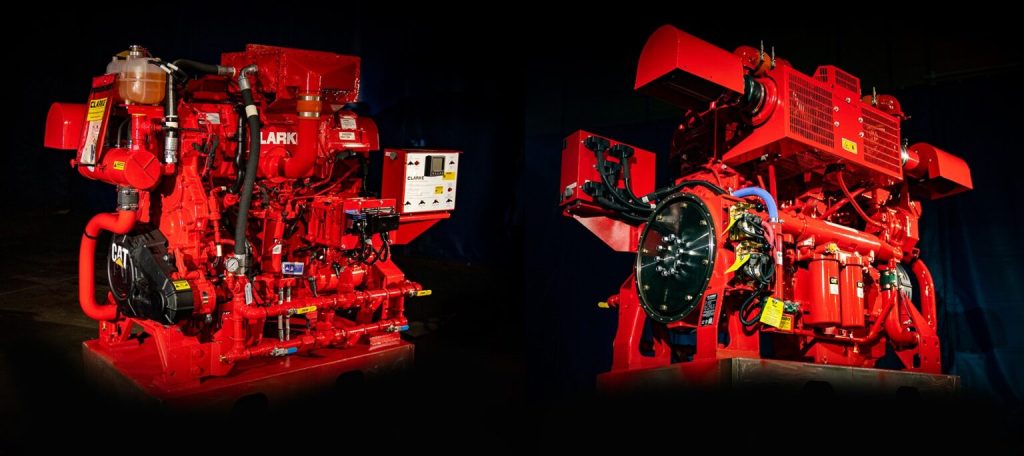

Clarke Fire Diesel Engine for Fire Pumps Applications in Pakistan

Fire Pump Room

August 2, 2025

NFPA-20 Diesel Engines for Fire Protection

August 24, 2025Introduction

When emergencies strike, reliability isn’t optional—it’s essential. Clarke Fire engines are engineered to deliver top-tier performance and unmatched dependability in fire pump applications worldwide. This post explores the capabilities and configurations of Clarke diesel fire pump engines, explains why they’re ideal for Pakistan, and highlights Excel Industrial Service as your premier local partner for spare parts, repair, and maintenance.

1. Clarke Fire: Engineering Diesel Fire Pump Engines with Global Reach

Clarke Fire has been a trusted global leader in diesel fire pump engines for over six decades, delivering UL/FM-certified solutions designed for critical water pressure and flow under the most demanding conditions clarkefire.com+1. Their engineering practices combine rigorous manufacturing standards and extensive testing processes, meeting diverse certifications like UL, FM, APSAD, VDS, and various country-specific codes Clarke.

2. Engine Models & Specifications

Engine Quick Search & Legacy Listings

Clarke offers an Engine Quick Search on their website, enabling precise filtering by criteria like type, emissions, RPM, and BHP—ideal for engineers customizing fire pump packages clarkefire.com. Historical listings include engine models and configurations with ratings such as:

- JU4H-UF42-P1 (Heat Exchanger, Mechanical, NSPS compliant)

- Power outputs in ranges like 106 bhp / 79 kW and up to 324 bhp / 242 kW https://eispak.com/.

JW6H Series Example

The JW6H family shows model-specific data with UL/FM-rated BHP/kW at various speeds:

- JW6H-UFAA60: 360 BHP at 1760 RPM (~268 kW)

- JW6H-UFAD70: 376 BHP at 1760 RPM (~280 kW); 399 BHP at 2350 RPM (~297.5 kW)

- JW6H-UFAD80: 422 BHP at 1760 RPM (~315 kW) and 400 BHP at 2350 RPM (~298 kW) clarkefire.com.

Legacy Model Example

Model JU4H-UFAD5G includes general specs:

- Weight: 1490 lb (676 kg)

- Displacement: 275 cu in (4.5 L)

- Compression Ratio: 19.0:1

- Bore & Stroke: 4.19″ × 5.00″ (106 × 127 mm)

- Engine Type: 4-stroke inline (John Deere 4045 Series Power Tech E) clarkefire.com.

3. Engine Options & Innovations

Clarke’s engineering team develops robust and customizable options for the world’s most demanding installations. These include:

- Pneumatic starting systems (UL Listed first in the industry)

- Full suite of options like battery kits, cooling loops, driveshafts, torsional couplings, filters, gauges, alarms, paints, tropicalization, bases, enclosures, and secondary starting methods clarkefire.com+1.

They’ve introduced innovations such as dual starting technology and specialized driveshaft couplings that simplify field alignment and reduce installation/maintenance time https://eispak.com/.

4. Why Clarke Fire Diesel Engines Suit Pakistan

- Unmatched reliability: UL/FM certification ensures dependable performance in emergencies—even under extreme climate conditions.

- Flexible power range: Engines from ~80 kW up to 300+ BHP, with options matched to various pump sizes.

- Customizable configurations: From cooling systems to starting mechanisms, Clarke engines can be tailored for Pakistan’s heat, dust, and operational realities.

- Innovation-ready: Clarke’s technology reduces installation complexity—vital in remote and challenging environments.

5. Excel Industrial Service: Trusted Company in Pakistan for Clarke Fire Engines

In Pakistan, Excel Industrial Service empowers clients with local access to Clarke solutions by:

- Supplying genuine Clarke diesel engine spare parts to keep systems mission-ready.

- Delivering expert Clarke engine repair and maintenance in Pakistan, including preventive programs, emergency support, and certified servicing.

- Offering technical guidance for selecting and customizing Clarke fire pump packages suited to local regulations, environmental conditions, and project demands.

- Ensuring fast response and logistical efficiency, minimizing downtime in high-stakes emergencies.

6. Technical Considerations for Performance in Pakistan

Altitude & Temperature Adjustments

Clarke’s ratings assume standard SAE conditions (29.61 in Hg, 77 °F, ~300 ft altitude). In Pakistan’s high-altitude/heat zones, expect:

- 3% horsepower reduction per 1,000 ft altitude above standard clarkefire.com+1.

- 1% reduction per 10 °F above 77 °F clarkefire.com+1.

NFPA 25 Compliance

Clarke fire pump engines are factory-tested and rated per NFPA 25 (testing and maintenance of water-based systems) and SAE Standard J1349 clarkefire.com+1.

Conclusion & Local Call to Action

For dependable fire safety solutions in Pakistan, Clarke Fire Diesel Engines offer unmatched reliability, flexibility, and certification. Excel Industrial Service provides seamless local access to Clarke’s genuine spare parts, expert repair, and precision maintenance—ensuring critical systems are always mission-ready.

Ready to build, service, or upgrade your Clarke fire pump engine setup? Connect with Excel Industrial Service today and ensure your systems meet the highest standards of performance and safety.

Clarke Fire Diesel Engine Options — Tailored Performance for Every Need

Flexible Engineering for Unique Environments

Clarke Fire understands that not every installation is the same. Whether you’re working at high altitude, in marine environments, or places with high humidity or dust, Clarke’s engine options are designed to adapt. For instance, stainless-steel instrument panels or corrosion-resistant cooling systems ensure durability—even in the most demanding settings.

Their engineering team is dedicated to providing purpose-built solutions—ranging from advanced starting systems to comprehensive monitoring packages—to address the unique challenges of each use case.

Core Categories of Options

From the site, Clarke groups its customizable additions into the following categories—each enhancing a specific aspect of the engine’s reliability or functionality:

- Battery Kits

- Cooling Loops

- Driveshafts

- Torsional Couplings

- Air Filters & Cleaners

- Exhaust Components

- Instrument Panels

- Alarms & Gauges

- Fuel Connection Hoses

- Protective Guards

- Paint Finishes

- Tropicalization Treatments

- Vertical Bases

- Enclosures

- Secondary Starting Methods

Noteworthy Options Highlighted

Paint Finishes

Clarke provides both a standard paint finish and a more durable epoxy coating—offered through downloadable product brochures.

Stainless Steel & Corrosion Resistance

Stainless-steel components, such as instrument panels, are offered for environments where corrosion resistance is critical—protecting electronics and instruments in coastal or chemical-exposed installations.

Starting Technology & Silencers

Clarke pioneered innovative features such as UL-listed pneumatic starting systems—especially suitable for rapid deployment needs. Additionally, sound-attenuated enclosures and exhaust silencers can be specified to minimize noise in installations where passengers or staff are nearby.

Instrumentation & Alarm Integration

Engine packages can include comprehensive instrumentation—gauge readouts, alarm systems (covering fuel, oil, temperature, etc.), and digital displays housed in rugged or NEMA 4X-rated enclosures.

Marine-Grade Cooling & Enclosures

For marine environments or highly corrosive conditions, Clarke offers sea-water-compatible cooling loops and weatherproof, sound-attenuating enclosures.

Why These Options Matter—Particularly in Pakistan

- Corrosion from Weather: Coastal megacities like Karachi, or industrial zones with chemical exposure, benefit from stainless or epoxy-coated systems.

- Limited Access to OEM Support: With Excel Industrial Service, these specialized Clarke options and parts become accessible locally—with proper installation and maintenance support.

- Noise Restrictions: Urban areas may restrict noise—sound-attenuating enclosures and silencers offer a compliance-friendly solution.

- High Ambient Heat & Dust: Enhanced cooling loops and air-cleaning systems ensure engine reliability even under harsh, dusty, or high-temperature conditions.

- Customized Installations: From mounting bases to couplings and enclosures, Clarke’s options help systems conform to local site specifications—and Excel can advise on the right configuration.

Clarke Fire Engine Options: Customizing Diesel Fire Pump Engines for Pakistan

- Clarke engine options Pakistan

- Clarke diesel fire engine customization

- Clarke corrosion-resistant fire pump engines

- Clarke engine starting methods

- Clarke fire pump silencers Pakistan

- Clarke paint and enclosure options

- Excel Industrial Service Clarke customization

Structure Suggestion:

- Intro — The value of modular engine options.

- Overview — Purpose behind Clarke’s flexibility in customization.

- Detailed Option Groups — Walk through each category, with focus on how each serves real-world needs, including local environments.

- Local Relevance — Why Excel Industrial Service is your go-to partner for selecting, supplying, and installing these options in Pakistan.

- Case Scenario Examples — For example, a fire pump installation in a Karachi data center needing noise control, dust filtration, and stainless components.

- Closing CTA — Encourage readers to reach out to Excel Industrial Service for bespoke Clarke engine packages tailored to Pakistan’s challenges.

Summary

This rewrite extracts Clarke’s key Engine Options offerings—such as protective coatings, starting systems, instrumentation, cooling, and enclosures—without copying their wording. It reframes these options around their practical importance, and positions Excel Industrial Service as the expert local provider integrating Clarke solutions in Pakistan.

Clarke Fire Diesel Engine Maintenance Kits: Your Guide to Reliable Fire Pump Maintenance

1. Why Maintenance Kits Matter for Clarke Engines

Clarke Fire’s maintenance kits are thoughtfully crafted solutions that help ensure diesel fire pump engines remain dependable and compliant. Built around a two-year service cycle, these kits simplify the tasks recommended by NFPA 25, the standard guiding inspection, testing, and maintenance of water-based fire protection systems.

2. What’s Inside the Annual Maintenance Kit

The first tier of Clarke’s maintenance strategy is the Annual Maintenance Kit. It includes the essential filter components needed yearly:

- Oil filter for Clarke Diesel Engine

- Fuel filter for Clarke Diesel Engine

- Air filter for Clarke Diesel Engine

- Zinc anode (zinc electrode) for Clarke Diesel Engine

These items help keep your engine clean, fuel-efficient, and protected from corrosion.

3. What the 2nd-Year Supplemental Kit Covers

The Second-Year Supplemental Kit is tailored to address wear and coolant system needs and contains:

- Belts Clarke for Diesel Engine

- Heat exchanger for hoses Clarke Diesel Engine

- Heater hoses for Clarke Diesel Engine

- Gaskets for Clarke Diesel Engine

This ensures continuity of care, especially for parts subject to wear or heat-related strain.

4. Tailored Kits for Specific Engine Models

Clarke organizes maintenance kits by engine model. For a given model—identified by its serial number and purchase data—you can request either the annual kit or the supplemental kit. Some kits come in stock, while others are made to order.

For instance, heat exchanger-cooled engines like the JU4H, JU6H, JW6H, DT2H, and C18H0 series each have dedicated BOM (Bill of Materials) kit numbers associated with them. If the supplemental kit isn’t immediately available, Clarke can work with you directly to ensure you get the right parts.

5. Why Authenticity Matters: Genuine Clarke Parts

Using only Clarke-certified parts is vital for safeguarding system performance and longevity. Unauthorized or counterfeit parts can compromise engine function, possibly void warranties, and tragically, undermine fire safety.

6. How Clarke Verifies Authentic Parts

Every Clarke engine carries a laser-engraved nameplate with a unique QR code. Scanning it directs you to a secure page on ClarkeFire.com where you can verify details like model, serial number, rating, and access useful documentation such as manuals, startup checklists, and maintenance kit info.

7. Warranty Benefits Aligned with Maintenance Compliance

Clarke provides a generous warranty: standard coverage for two years from commissioning (or 18 months post-shipment). But here’s the bonus: if maintenance is performed per NFPA 25 guidelines, you automatically receive an additional third year—no added cost, no fine print.

8. How to Get the Right Kit for Your Engine

To order the correct maintenance kit, you’ll need:

- Engine serial number

- Original purchase date

These details help Clarke confirm the right BOM part number, especially for Supplemental Kits that vary by production run or configuration.

9. EIS Expert Support: Always On Call 24/07

Need help figuring out which kit fits your engine? Clarke’s customer support is equipped to assist—via email or phone—and can even guide you to purchase parts individually if a full kit isn’t ideal.

Summary

| Feature | Details |

|---|---|

| Annual Kit | Oil, fuel, air filters + zinc anode |

| 2nd-Year Supplemental Kit | Belts, hoses, gaskets for coolant system maintenance |

| Model-Specific | Kit codes vary by engine series (JU, JW, DT, C series, etc.) |

| Authenticity | QR-coded nameplate for verification |

| Warranty | 2 years standard; extra year with proper NFPA 25 service |

| Support | Clarke help desk: parts ordering, advice, backup |

Local Partner Highlight: Excel Industrial Service (Pakistan)

In Pakistan, Excel Industrial Service acts as your trusted local partner to make Clarke maintenance effortless. Here’s how they help:

- Genuine Parts Supply: They stock and source Clarke-certified maintenance kit components and filters.

- Expert Maintenance Support: Whether it’s routine service or Supplemental Kit replacement, Excel coordinates maintenance to keep Clarke engines compliant and efficient.

- Warranty Assistance: They guide adherence to NFPA 25 service requirements—helping secure that valuable third-year warranty.

- Customization & Guidance: Excel can assist in identifying the right kit for your engine’s model and serial, and liaise with Clarke when custom BOMs are needed.

Whether you’re managing fire pump engines for industrial sites, hospitals, or high-rise infrastructure, Excel Industrial Service ensures Clarke systems operate safely and reliably in Pakistan.

Let me know if you’d like this expanded into a longer guide, include visuals, or adapt it into localized content for Pakistan and Excel Industrial Service!

For any query or to discuss about Clarke Fire Diesel Engines for Fire Pump Packages related to

– New Engines of Clarke Fire Diesel Engine in Pakistan

– Replacement of Clarke Fire Diesel Engines in Pakistan

– Spare Parts for Clarke Fire Diesel Engines in Pakistan

– Repair & Maintenance services for Clarke Fire Diesel Engines in Pakistan

Feel free to contact!

Mr. Rahil Ayoub Ansari

+ 923453230843

rahil(at)eispak.com

#ClarkeFireDieselEngine #DieselFirePumpEngine #ClarkePakistan #ExcelIndustrialService #FirePumpEngine #DieselEngineSpareParts #ClarkeRepairPakistan #EngineMaintenancePakistan #ULFMFirePump #FireSafetyPakistan #ClarkePartsPakistan #FirePumpControllers #DieselFireProtection #ClarkeEngineOptions #IndustrialFireSafety #ClarkeFirePumpDrivers #FirePumpInstallation #EmergencyPowerEngine #ClarkeAuthorizedService #FirePumpSolutions #DieselEngineReliability #ClarkeEngineModels #FireProtectionEquipment #PakistanFirePump #FirePumpMaintenance #ClarkeEngineRepair #DieselFirePumpSupplier #ULListedEngines #FMApprovedEngines #ClarkeInnovation #FirePumpCustomization #EngineCoolingOptions #ClarkeTropicalization #FirePumpParts #FirePumpTesting #NFPA25Compliance #ClarkeEngineSpecs #DieselFirePumpPackages #FirePumpEmergencyReady #ClarkeGlobalStandards #FireSafetyEngineering #ClarkeEngineCustomization #FirePumpAutomation #EngineStartingOptions #ClarkeBatteryKits #FirePumpControllers #EngineDriveshafts #ClarkeAlarmsGauges #FirePumpEnclosures #ClarkeEngineServicePakistan #FirePumpRegulations #ClarkeEngineSupplier #ClarkeLegacyEngines #FirePumpDownloads #ClarkeQuickSearch #DieselEngineOptions #FirePumpEngineRatings #ClarkeHeatExchanger #DieselFirePumpCompliance #ClarkeNSPSCompliant #EngineAltitudeCorrection #FirePumpTemperatureRating #ClarkeTestingStandards #EnginePerformancePakistan #FirePumpLifecycle #ClarkeWorldwide #DieselFirePumpSupport #FirePumpInstallationTime #ClarkeDualStarting #FirePumpAlignment #FirePumpOperationalReliability #ClarkeTSPMPanel #FirePumpInstrumentation #EngineInstrumentation #FirePumpGlobalCerts #ClarkeFireSafety #EmergencyEnginePackages #DieselFirePumpSpecs #ClarkePowerGen #FirePumpPowerRatings #EngineWeightSpecs #ClarkeCompressionRatio #FirePumpBoreStroke #EngineDisplacementSpecs #FirePumpAltTempCorrection #ClarkeEngineTesting #DieselFirePumpVendor #ClarkeEngineSupport #FirePumpMaintenanceTips #PakistanFireSystems #EngineServiceNetwork #ClarkeEngineInventory #FirePumpDocumentation #ClarkeEngineAdvantages #FirePumpEngineeringPakistan #DieselFirePumpLifecycle #ClarkeEngineDurability #FirePumpServiceProviders #ClarkeFuelOptions #FirePumpCoolingLoops #ClarkeAirFilters #FireSafetyEquipmentPakistan