- Connect With Us!

- +92 345 3230843

- +971 54 454 5232

- solutions(at)eispak.com

Annual Fire Pump Performance Testing in Pakistan as per NFPA 25

Oil Marketing Companies in Pakistan – Market Share & Retail Network 2025

August 26, 2025

TORNATECH DIESEL ENGINE FIRE PUMP CONTROLLERS – MODEL GPD – INSTALLATION AND MAINTENANCE MANUAL

August 28, 2025I. PURPOSE

This procedure establishes guidelines for the annual testing of all fire pumps in buildings

A joint venture between National Fire Protection Associates of Pakistan (NFPA Pakistan) and Excel industrial Services now offering Annual Fire Pump Performance Testing Services in Pakistan as per NFPA 25 under expert Certified Fire Protection Specialist – CFPS from NFPA USA. This procedure is based on NFPA 25 Standard for the Inspection, Testing and Maintenance of Water-Based Fire Protection Systems, Chapter Eight.

II. PERSONNEL AFFECTED

- Fire Safety Specialist and Fire Safety Inspectors from the NFPA Pakistan Environmental Health and Safety, Fire Safety Unit.

III.DEFINITIONS

- FSS – Fire Safety Specialist

- FSI – Fire Safety Inspector

IV RESPONSIBILITIES

- The FSS or FSI is responsible for the annual flow testing of all fire pumps in

A- buildings within their area of responsibility. Upon identification of any deficiencies it is the responsibility of the FSS and FSI to issue work orders and work with the appropriate personnel to see that repairs and or replacements are made and completed to all deficient materials.

B- The landlord is responsible for the annual flow testing of all fire pumps in buildings and upon identification of any deficiencies it is the responsibility of the landlord to correct all deficiencies.

V PROCEDURES

A- The annual test shall be conducted under churn, 100% of pump rating, and 150% of pump rating of the fire pump by controlling the quantity of water discharged through approved test devices. If available suction supplies do not allow flowing of 150 percent of the rated pump capacity, the fire pump shall be permitted to operate at maximum allowable discharge without having the suction pressure reduce to less than 20psi. Weekly/monthly inspection checklists should also be followed during the annual testing.

B- Use Hose Monsters to help disperse the water and increase safety.

C- Pump suction and discharge pressures and the flow measurements of each hose stream shall be determining the total pump output. Care shall be taken to prevent water damage by verifying there is adequate drainage for the water discharge from hoses.

D- The pertinent visual observations, measurements, adjustments and documentation specified in the following checklists shall be conducted while performing the fire pump test under the specified condition.

a. Pretest inspection/preparations

(1) Check for A/C power at pump controller.

(2) For diesel fire pumps, make sure fuel level is adequate and not below 3/4 full.

(3) Change out current gauges on suction and discharge with calibrated liquid filled gauges.

(4) Verify alignment of all valves in sprinkler room are in correct positions.

(5) Make sure test header drain is closed.

(6) Record static pressure of suction and discharge with fire pump off.

b. No-flow condition (churn) test:

(1) Follow same procedure as the weekly/monthly fire pump test procedure.

(2) Check circulation relief valve for operation to discharge water.

(3) Check the pressure relief valve (if installed) for proper operation.

(4) Check for proper water displacement off fire pump packings.

(5) Record suction and discharge pressures

(6) Record amps and volts if digital readings are available on the pump controller or by shark meter.

(7) Record RPM readings

c. 100% of rated flow test:

(1) Open test header main isolation valve SLOWLY until the test header is full.

(2) Manipulate the test header valves until the pitot readings at the hose monsters have achieved the desired flow for 100% of fire pump rating. (Refer to pump test sheets for desired psi)

(3) Take your amp and volt readings from the digital output on the fire pump controller or from the installed shark meter.

(4) Record RPM readings.

(5) Record the simultaneous (approximately) readings of pump suction pressure, discharge pressure and hose stream pitot readings.

(6) Monitor pump packaging temperature.

d. 150% of rated flow test:

(1) Manipulate the test header valves until the pitot readings at the hose monsters have achieved the desired flow or as close as possible to achieve 150% of fire pump rating. (Refer to pump test sheets for desired psi)

(2) Take your amp and volt readings from the digital output on the fire pump controller or from the installed shark meter.

(3) Record RPM readings.

(4) Record the simultaneous (approximately) readings of pump suction pressure, discharge pressure and hose stream pitot readings.

(5) Monitor pump packaging temperature.

e. Water supply test

(1) Shut down the fire pump at the controller.

(2) Shut down the jockey pump.

(3) Open all test header valves to the full open position.

(4) Record pitot readings at each test header outlet.

(5) Record pump suction and discharger pressures.

f. Realignment

(1) After all readings have been completed close test header valves

(2) Close test header main isolation valve.

(3) Open test header drain line.

(4) Open test header valves to support draining of test header.

(5) Once test header is drained, close test header valves.

(6) Close test header drain line.

(7) Cap test header ports.

(8) Verify valves of the fire pump are back in normal operating positions.

(9) Turn jockey pump on to bring system up to desired pressure.

(10) Once system up to desired pressure, turn main pump on.

(11) Verify main power has been restored to fire pump.

All information obtained will be returned to the Building Fire Marshal for further calculation and graphing of the fire pump test results.

VI. REFERENCES

NFPA 25 Standard for Inspection, Testing, and Maintenance of Water-Based Fire Protection Systems.

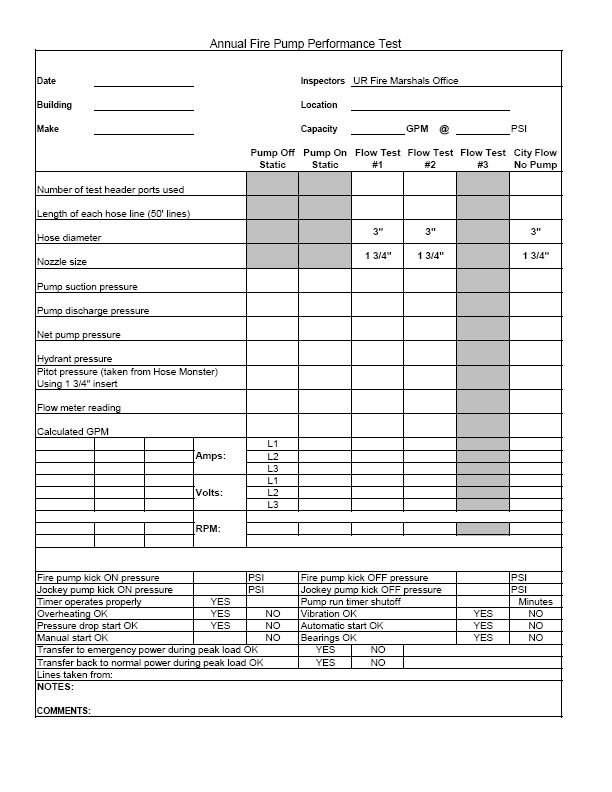

VII. APPENDICES/FORMS

Appendix I – Fire Pump Test Sheet – Blank Form

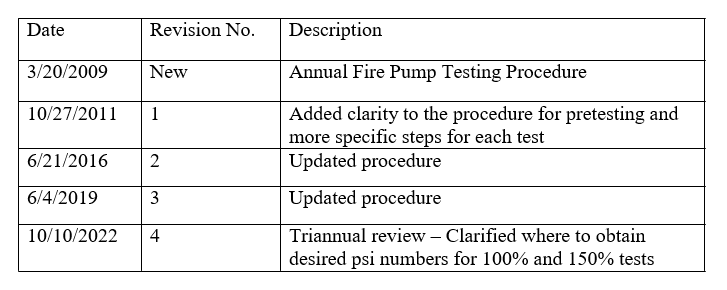

VIII. SAMPLE REVISION HISTORY

Appendix I

Fire Pump Annual Performance Test Report (Sample)

Annual Fire Pump Testing Procedure (Step-by-Step – NFPA 25 Based)

Our testing follows the global NFPA 25 standard and includes multiple performance stages:

1️⃣ Pre-Test Inspection & Preparations

Before testing begins, our team ensures the fire pump system is safe and ready for evaluation:

- Verify A/C power supply at the pump controller.

- For diesel fire pumps, check that fuel level is at least ¾ full.

- Replace suction and discharge gauges with calibrated liquid-filled gauges.

- Confirm valve alignment in the sprinkler room.

- Ensure test header drain is closed.

- Record initial suction and discharge pressures with pump off.

2️⃣ Churn Test (No-Flow Condition)

- Conducted with fire pump running but no water flowing.

- Record suction and discharge pressures.

- Check circulation relief valve and pressure relief valve (if installed).

- Inspect pump packings for proper water displacement.

- Record amps, volts, and RPM readings from pump controller.

3️⃣ 100% of Rated Flow Test

- Open test header valves slowly to achieve 100% of rated flow.

- Measure flow using Hose Monsters or approved devices.

- Record suction pressure, discharge pressure, pitot readings, amperage, voltage, and RPM.

- Monitor pump temperature to prevent overheating.

4️⃣ 150% of Rated Flow Test

- Open valves to increase water discharge up to 150% of pump rated capacity (or maximum available).

- Record suction/discharge pressures, pitot readings, amps, volts, and RPM.

- Verify that suction pressure does not fall below 20 psi to protect the system.

- Monitor pump packaging temperature for safe operation.

5️⃣ Water Supply Test

- Shut down the fire pump and jockey pump.

- Fully open test header valves and record pitot readings.

- Document suction and discharge pressures to confirm water supply capacity.

6️⃣ System Realignment After Testing

- Close all test header valves and main isolation valves.

- Drain and cap test header lines.

- Restore fire pump valves to normal operating position.

- Restart jockey pump and bring system to pressure.

- Restore main pump to normal standby mode.

- Verify system power and readiness.

7️⃣ Documentation & Reporting

All observations, readings, and measurements are documented in the Fire Pump Test Sheet. Results are compiled into a Certified Fire Pump Performance Report, stamped and signed by NFPA CFPS specialists, and provided to the client for:

- Civil Defense approvals

- Insurance compliance

- Internal audits & safety documentation

Importance of NFPA 25 Fire Pump Testing in Pakistan

Annual Fire Pump Testing is not just a compliance requirement — it is a life-saving practice. Many fire incidents in Pakistan have turned catastrophic due to non-functional pumps, faulty valves, or inadequate water supply.

By ensuring pumps are tested annually, facilities gain:

- Legal compliance with fire safety authorities.

- Reduced insurance risks and better premium negotiations.

- Increased safety for employees, assets, and infrastructure.

- Reliable firefighting response in case of emergency.

Why Choose NFPA Pakistan & Excel Industrial Services?

- Certified Expertise – NFPA Certified Fire Protection Specialists (CFPS).

- International Standards – Testing strictly based on NFPA 25 guidelines.

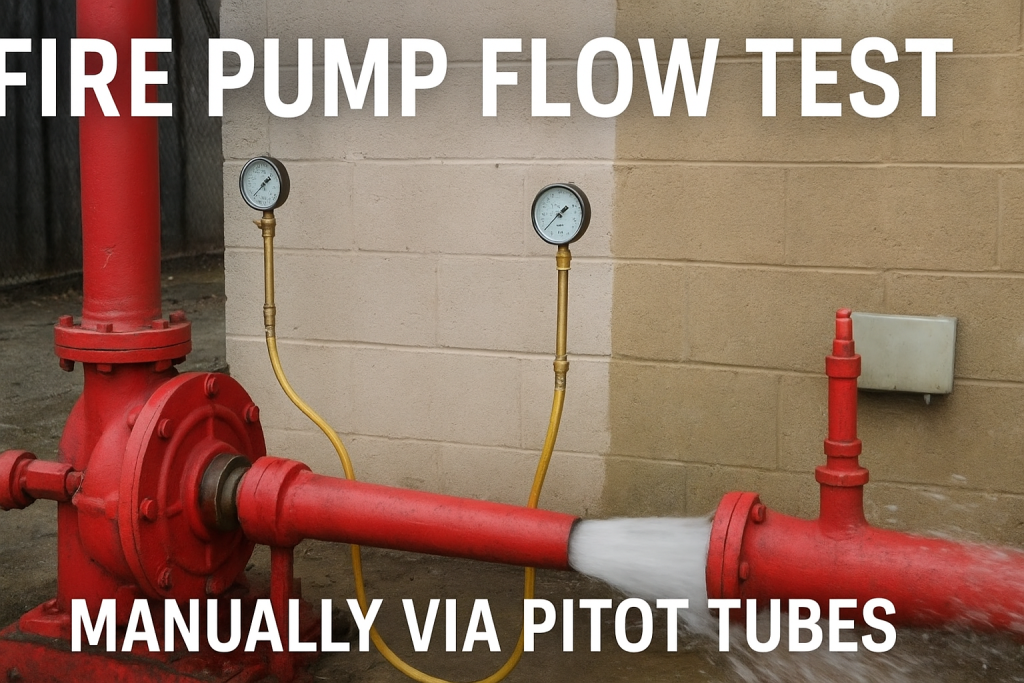

- Advanced Equipment – Use of calibrated gauges, pitot tubes, Hose Monsters, and digital meters.

- End-to-End Service – From testing to commissioning and after-sales support.

- Nationwide Availability – Karachi, Lahore, Islamabad, Faisalabad, Multan, Quetta, Peshawar, and all industrial hubs.

- Trusted Clients – Serving oil marketing companies, storage terminals, industries, commercial complexes, hospitals, and universities.

At Excel Industrial Services, we’re always thinking about your investment and what it means for the longevity of the equipment. That is why we are employing useful tools to perfect the art of alignment during our pre-checks. Minimal setup, maximum life!

Nothing sounds better, than a fine-tuned machine!

We love seeing older technology meet new. It reminds us as to why we keep improving in this Industry!

However you choose to run your systems, trust that Excel Industrial Services has your back! And yes, we can provide parts and replacements for everything you see in the field. We are your partner through and through!

Excel Industrial Services with National Fire Protection Associates of Pakistan (NFPA Pakistan) now introducing Latest Technologies for Fire Pump Flow Testing & Hydrants Flow Testings in Pakistan

1. Traditional vs. Modern Methods

Traditional (Old) Methods

- Pitot Tubes & Hose Monsters: These measure nozzle pressure to calculate flow rate via the formula Flow (GPM) = 29.84 × √Pitot Pressure × Nozzle Coefficient². Simple, but prone to human error and calibration drift. 91 Fire Pump

- Mechanical Gauges & Test Headers: Liquid-filled gauges at suction/discharge points and manifold-equipped test headers are well-established methods but require manual setup and observation. 91 Fire Pump

Modern (New) Technologies

- Portable Ultrasonic Flow Meters: Devices like the UF801P use clamp-on ultrasonic sensors to take non-intrusive, real-time flow and pressure readings—even exporting results for reporting. Benefits include zero pipe modifications, fast setup, and high accuracy. seztec.us

- IoT-Enabled and Smart Monitoring Systems: Fire pump systems now feature real-time dashboards monitoring pressure, flow, and system health remotely. Predictive analytics anticipate maintenance before failures occur. Koorsen BlogP Market Research

- Advanced Venturi-Based Test Meters: Companies like Global Vision Inc. (GVI) manufacture US-made machined venturi flow meters with digital and glycerin-fill gauge options, offering +/-0.5% accuracy across 12.5–10,000 GPM ranges. GVI FlowNoor Scientific

- Automated Mobile Testing Systems: Max Flow Systems’ “Ultimate Draft System” streamlines pump testing with automated controls via smartphone or tablet. It requires only one operator, performs six tests in an eight-hour shift, and avoids tip changes mid-test. Max Flow Systems

- Mobile Certified Testing Vans: UL Solutions offers mobile fire pump testing vans that can handle pumps up to 3,000 GPM—complete with all test functions, immediate certification, and on-the-spot reporting. UL Solutions

2. Companies Leading the Way in Fire Pump & Hydrant Flow Testing

Here are standout companies delivering state-of-the-art fire pump flow testing technologies in the U.S.:

- Max Flow Systems: Innovators of the “Ultimate Draft System”—portable, automated, smartphone-controlled pump testers that redefine speed and precision. Max Flow Systems

- Global Vision Inc. (GVI): Produces high-precision, machined venturi flow meters (with digital and analog options) for highly accurate and durable testing. GVI FlowNoor Scientific

- UL Solutions: Well-known authority delivering on-site fire pump performance testing via mobile labs that meet NFPA standards—providing certifications immediately after testing. UL Solutions

- Coltraco Ultrasonics (UK-based, but used globally including the U.S.): Offer clamp-on ultrasonic flow meters (Portasonic & Permaflow) that are non-intrusive, highly accurate, and low-maintenance—ideal for long-term deployment or field use. Coltraco Ultrasonics

- Hurco Technologies: Offers automated fire flow testing systems with wireless transmitters, pitotless diffusers, and detailed software-generated reports—perfect for hydrant and distribution system testing. Hurco Technologies

3. Benefits of Modern Technologies

| Advantage | Description |

|---|---|

| Speed & Efficiency | Automated systems reduce test times dramatically (e.g., 6 tests in a day by Max Flow) compared to manual setups. |

| Accuracy & Reliability | Venturi meters and ultrasonic systems offer precision, limited wear, and consistent readings. |

| Non-Invasive Setup | Clamp-on designs like UF801P and Portasonic avoid cutting pipes or interrupting systems. |

| Real-Time or Remote Monitoring | IoT-enabled tools push data to dashboards, enabling proactive maintenance. |

| Integrated Reporting | Systems like Hurco and Max Flow provide immediate, graph-based digital test reports. |

Summary

The shift from old-school pitot gauges and manual test headers to modern solutions—like ultrasonic flow meters, IoT analytics, automated mobile systems, and certified vans—marks a new era of safe, fast, accurate, and efficient fire pump flow testing. Leading US companies such as Max Flow Systems, Global Vision Inc., and UL Solutions, along with innovations from Coltraco and Hurco, are defining what the future of fire safety testing looks like.

Let me know if you’d like a ready-made infographic or downloadable PDF summarizing these tools and innovations for your blog or training materials!

We offer Lates technologies to conduct Fire Pump Flow Testing and Hydrant Flow Testing

Some of Lates technologies to conduct Fire Pump Flow Testing and Hydrant Flow Testing which can be arrange on demand to conduct best accuracy of your flow testing with complete automation systems.

MECON GmbH

Equipped with state-of-the-art software and an app, every measurement displays water pressure, flow rate, and total flow volume from the very beginning. The hydrant tester measures seepage rates and performs firefighting water or well water flow tests. Optionally, the temperature can be measured and documented.

For water utilities, there is the option, especially during flushing campaigns, to measure FNU values via the separate turbidity measurement¹ and thus optimize the flushing strategy efficiently and in a resource-conserving manner.

Automatic data transmission via Bluetooth from the hydrant tester to the mobile device using the app.

The measurement process can now be controlled not only via the easily readable display but also via the proven software and app from wasserkarte.info. All measurement data for pressure, flow, temperature, and turbidity¹ are transmitted live from the hydrant tester to the app. Measurement protocols and diagrams are displayed directly as a preview. The all-in-one solution for hydrant maintenance—from digital documentation, planning, and localization to performance testing and maintenance.

¹Turbidity measurement is performed using a separate sensor that connects to the mag-flux HTL.

Hose Monster – USA

An annual fire pump flow test is a key step in ensuring the proper functioning of a fire protection system. In this video, we show you how simple it is to flow test a fire pump using Hose Monster’s patented Pitotless Nozzles and Little Hose Monsters. It’s the most accurate way to gauge your fire pump’s flow. Testing, Apparatus Fire Pump Testing, Hydrant Flow Testing, Fire Pump Testing, Standpipe and PRV Testing.

Hydra Tap

The Riptide Flow Testing System™️ is a UL Listed stackable, totally modular and universally compatible flow testing system. For Fire Pumps, Fire Dept Apparatus, Fire Hydrants, Standpipes, PRV Testing

It is comprised of TEN unique diffuser models with as many as four streams in a single diffuser.

Cam-locks come standard with every single Riptide™️ so there are no additional costs to stack.

Single Action • Double Action • Triple Action • Quad Action • LDH All Available

📢 Conclusion – Stay Compliant, Stay Protected

Annual Fire Pump Performance Testing is mandatory under NFPA 25 and an essential part of fire protection system maintenance. With NFPA Pakistan and Excel Industrial Services, you gain a reliable testing partner with certified expertise, advanced equipment, and nationwide service availability.

👉 Ensure your fire pumps are always in compliance, always reliable, and always ready. Contact us today for NFPA 25 Annual Fire Pump Testing in Pakistan.

firepumptesting #annualfirepumptesting #NFPA25 #firepumptestingPakistan #firepumptestingKarachi #firepumptestingLahore #firepumptestingIslamabad #firepumptestingFaisalabad #firepumptestingMultan #firepumptestingQuetta #firepumptestingPeshawar #NFPAcertified #firepumpinspection #firepumpflowtest #firepumpmaintenanceservices #fireprotectionPakistan #firepumptestingservices #firepumptestingcompanies #firepumptestreport #CFPS #firepumpcommissioning #firepumpinstallation #firepumprepair #NFPApakistan #ExcelIndustrialServices #firesafetyservicesPakistan #firepumpaudit #firepumpflowtesting #oildepotsafety #industrialfiresafety #firesafetyconsultantsPakistan #NFPAfiresafety #ULFMfirepumps #firesafetysolutionsPakistan #firepumpstandards #NFPAapprovedtesting #firepumpcompliance #firesafetypakistan #oilterminalfiresafety #firepumpcertification #firepumpcontractorPakistan #firepumptestKarachi #firepumptestLahore #firepumptestIslamabad #firepumptestPunjab #firepumptestSindh #firepumptestKPK #firepumptestBalochistan #firesafetytrainingPakistan #NFPAfirepump #firesafetyPakistan #firepumpinspectionPakistan #NFPA25compliance #firepumpmonitoring #firepumpperformance #firepumpservicePakistan #firepumpconsultants #firepumpstandby #firepumpannualtest #firepumpturnkeysolutions #firesafetyauditPakistan #fireprotectionservicesPakistan #firepumpinstallationPakistan #NFPAfireprotection #firepumpmaintenancePakistan #firepumpengineers #firepumpcontractor #firesafetyaudit #firepumpafterservice #firepumpcalibration #firepumpflowreport #firepumpmanagement #firepumpperformancePakistan #firepumpsystemtesting #firepumptechnicalservices #firepumpinspectionreport #firepumpauthorities #firepumpannualinspection #firepumpcertificationPakistan #NFPA25firepumpPakistan #firesafetypartnerPakistan #firepumpnationwide #firepumpemergencyservices #firepumpconsultancyPakistan #firesafetysolutions #firepumpqualitytesting #firepumpindustrialtesting #firepumpnationwidePakistan #firepumpfacilities #firepumpoilindustry #firepumpofficialreport #firepumpcomplianceservices #firepumpinsurancecompliance #firepumpstandardservices #firepumpregulationPakistan #firepumprequirementPakistan